A car battery, which is medium-large sized Lithium-ion battery operating Electric Motor Vehicle, activates its lithium ion movement between the anode and the cathode to produce electricity leading to the possibility of charging and discharging.

DE&T continues to study technologies and develop battery process equipment for the production of various standards of secondary battery products according to customer needs. Furthermore, we promise to become a world-class secondary battery equipment supplier.

Module

Module

Pack

Pack

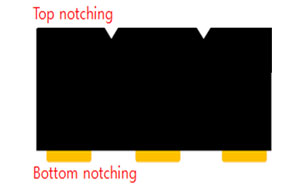

Previous Notching

Previous Notching

After Notching

After Notching

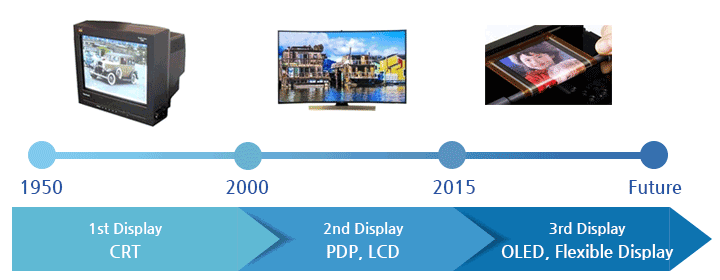

Display was developed from 1st generation, CRT to 2nd generation display(PDP, LCD). Now, it is being developed to 3rd display, OLED and flexible display.

Development of Display

A Liquid Crystal which is a core component of LCD blocks or passes light. However, since the liquid crystal is not able to emit light by itself, it needs a backlight which can change the elecric energy to the light energy for showing visual information on the LCD panel.

Because the OLED, the next generation display of the LCD uses light emmiting diodes, it needs less elements such as backlignt unit, color filters and has simpler structure than the LCD. Therefore, the OLED is lessened the thickness and the weight one third of LCD and has excellent image quality and less power consumption. Also, plastic materials can be used for OLED to implement various forms like flexible and bendable displays.

Now, the smartphone market using AMOLED has been rapidly grown and captures the OLED market. However, accrording to the development of IoT technology including automotive, demands for various forms of displays are increasing. In addition to this, the development for large size and flexible OLED, we expect the change of display paradigm and huge growth.