| Scan Speed | 500mm/s |

|---|---|

| Inspection Defect Size | ≥50um (Edge as standard) |

| Illumination type | Exterior Coaxial, Side illumination |

| Align Type | Vision Align |

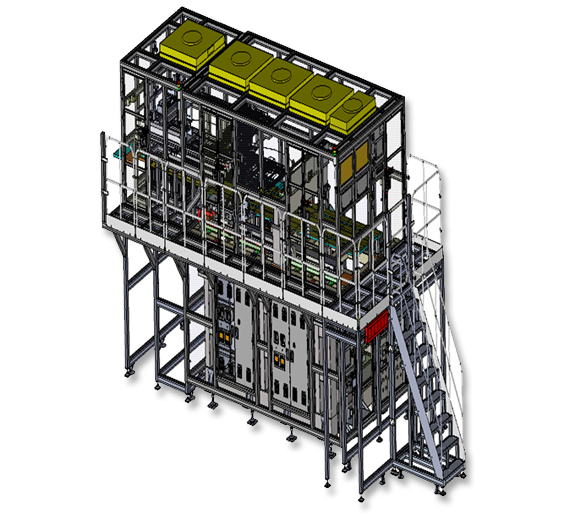

| Dimension | L 9,750 * W 3,450 * H 4,040(㎜) |

* The above specification changes according to the Inspection Cell size.